1. Building photovoltaic: BAPV and BIPV

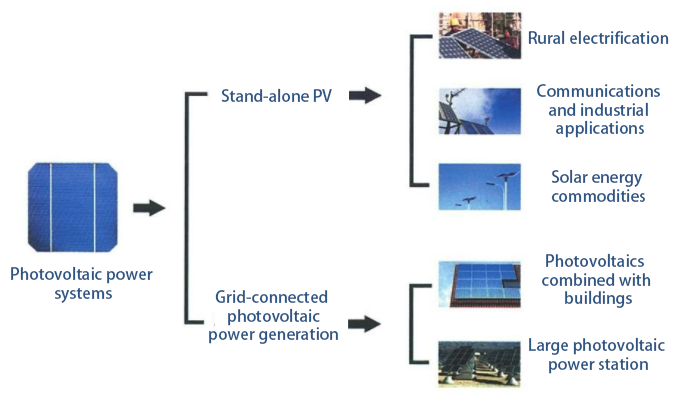

Hello everyone, today I will talk to you about BIPV. Before talking about BIPV, let’s take a look at the position of BIPV in photovoltaic power plants.

Figure 1: Classification of photovoltaic power plants

Building photovoltaics are distributed photovoltaics. Compared with centralized photovoltaic power plants, they have the advantages of saving land, nearby consumption, and power peak regulation. Building photovoltaic is to combine photovoltaic power generation with buildings, and lay photovoltaic devices on the periphery of the building structure to generate electricity.

Building photovoltaics are divided into two categories:

1. BAPV, installed photovoltaic, Building attached photovoltaics, photovoltaic system attached to the surface of the building.

2. BIPV, Building Integrated Photovoltaic, Building integrated Photovoltaic, photovoltaic system becomes a direct building material.

BAPV is a simple bonding method suitable for retrofitting existing roofs. Install additional steel structure brackets or slide rails directly on the roof of the building, and fix photovoltaic panels to generate electricity. At present, the photovoltaic roofs that are “promoted by the whole county” adopt this method.

Figure 2: Typical application of BAPV

The main problems encountered by BAPV are:

1. Load. The load on the original roof does not meet the requirements for the second installation of photovoltaic panels, and the original roof needs to be re-strengthened. Some reinforcement is difficult. There are even news of snowstorms crushing roofs and strong winds blowing away photovoltaic panels.

2. Waterproof. BAPV will damage the original waterproof layer of the roof, and it will need to be repaired after it is built, causing drainage problems.

3. The safety and actual service life of photovoltaic panels. Auxiliary components such as inverters and junction boxes are often exposed to the outside, not to mention affecting the appearance, they are easily damaged and reduce the actual service life of BAPV.

BAPV is often a project that requires a one-time investment for many years, and the owner attaches great importance to the rate of return and safety. Once a major loss occurs, it will be difficult to effectively protect the rights and interests. And BIPV, photovoltaic and building integration, can avoid many problems of BAPV. It has the advantages of long life, reliable force, waterproof and reliable, and convenient for operation and maintenance.

BIPV classification and development

BIPV is a photovoltaic system that becomes a direct building material. At present, a series of photovoltaic building materials such as photovoltaic roofs, photovoltaic glass, photovoltaic curtain walls, and photovoltaic tiles have been developed.

Figure 3: BIPV-related products compared with BAPV

BIPV can be divided into crystalline silicon type and thin film type according to the material

Crystalline silicon type BIPV has high conversion efficiency, up to 25% for single crystal. Crystalline silicon cells are opaque, and crystalline silicon components are mainly used in opaque construction projects. Of course, the use of double-sided glass for crystalline silicon photovoltaic curtain walls can also meet certain light transmission requirements. The crystalline silicon type is the most familiar to everyone.

Thin-film BIPV is currently mainly cadmium telluride (CdTe) cells, copper indium gallium selenide (CIGS) cells, and perovskite solar cells.

The average efficiency for commercial applications of cadmium telluride is 14.7%. Copper indium gallium selenide batteries currently have the highest efficiency among thin film types, which can be close to 20%. The efficiency is not as good as the crystalline silicon type, but the thin-film type also has advantages that the crystalline silicon type does not have: adjustable transparency, better low-light performance, and better temperature coefficient. Ensure that it can maintain work in extreme conditions such as high temperature and low light.

Figure 4: Architectural Effect of Colored Thin Film Battery

Thin-film batteries are not a recent concept. Thin-film battery technology came out in the 1970s, surpassing crystalline silicon batteries in the limelight, and even called “next-generation photovoltaic technology”. Later, due to the difficulty in improving efficiency, it gradually died down.

Now, the outbreak of BIPV has brought new opportunities to thin-film batteries. At present, domestic companies in the thin-film field include Longyan Energy, Ruike New Energy, a subsidiary of Mingyang Intelligent, and Hangzhou Sina. However, crystalline silicon cells have giants in the photovoltaic industry. At present, the crystal silicon camp looks more gorgeous.

BIPV can be divided into building material type and component type according to the product expression form

The integration of “building material type” is more perfect, and photovoltaic cells are completely integrated into building materials, which may not be much different from traditional building materials in appearance. Higher requirements are put forward for the strength and performance of materials. “Building material type” is a relatively ideal form, but it has a high degree of customization, high strength requirements, and high cost.

Tesla photovoltaic tiles are “building material type”. According to Musk’s first batch of customer feedback, it is suitable for “financially insensitive” people, you can taste it carefully.

Figure 5: Pony and Tesla roof

“Component type” tends to be standardized products, combining photovoltaic modules and building components into an integral component, which is easier to distinguish from traditional building materials in appearance. At present, this is the mainstream in the market, mainly photovoltaic roofs, photovoltaic curtain walls, and photovoltaic sunshades. On the one hand, it can maintain the power generation efficiency of the modules to the highest degree and maximize the effective power generation area of the battery. However, standardized components also limit the application scenarios. At present, they are mainly used in large-area roofs such as industrial and commercial factory roofs, rainproof carports, and external curtain walls of large buildings.

Now photovoltaic module companies have also launched light-transmitting and colored photovoltaic curtain walls, providing design institutes with more optional design styles to meet certain architectural aesthetic design requirements.

Photovoltaic curtain wall has dual properties of photovoltaic and architecture, and it needs to be designed, constructed and installed at the same time as the building, and the cost is relatively high. In addition to the function of power generation, it is necessary to meet the requirements of building functions: external maintenance, transparency, mechanics, aesthetics, safety, etc. Building functional requirements are higher than photovoltaic power generation requirements, and building functional requirements must be met first, so sometimes photovoltaic properties are sacrificed, such as higher power generation efficiency, better lighting angle, greater power generation, etc.

The photovoltaic roof of King’s Cross Station in London, in order to meet the light transmission requirements, it can be seen that the cells are relatively sparse, sacrificing higher wattage and power generation efficiency.

Three generations of BIPV technology development

In summary, the process of BIPV technology development can be summarized.

In the first generation, the photovoltaic array is installed on the surface of the building with some additional supports and fixtures, and its appearance is similar to BAPV. Most of the crystalline silicon type BIPV is currently the mainstream.

In the second generation, thin-film batteries are the mainstay, and photovoltaic modules and building materials are integrated into one, with beautiful appearance. However, power electronic devices and wiring are inconvenient to arrange, with low reliability and high maintenance costs.

In the third generation, photovoltaic systems, building materials, and electric energy conversion supporting devices are all integrated. High customization requirements and high costs. Newer generations of technologies and materials need to be developed.

At present, domestic photovoltaic buildings mainly focus on the future incremental market. For large-scale public buildings without lighting requirements, such as shopping centers, crystalline silicon curtain wall solutions can be selected. For buildings such as office buildings with lighting requirements, thin-film batteries can be selected, and double-sided glass and crystalline silicon components with certain light transmittance can also be selected. There are many articles on BIPV’s market forecast and policy development, so I won’t go into details here.

Xiamen Lianbang Technology Co., Ltd. is a leading technology company in the field of solar energy and related sustainable technologies. We have the experience, capability and financial viability required to successfully implement affordable wind & photovoltaic systems and on/off-grid power system solutions and products. We provide turnkey services including assessment, design, permitting, procurement, installation, commissioning, and operation and maintenance. We take a creative approach to designing photovoltaic systems so that they are price-competitive, high-performance and attractive.

Comments are closed